Tailored engineered approach, custom chemistry, and experience.

FourQuest Energy delivers a tank cleaning methodology that’s tailor-made to each vessel or tank – changing the industry standard as well as enhanced mechanical cleaning. By optimizing our approach with custom chemicals from FQE Chemicals, we reduce the duration and number of crew member that enter the tank, no hazardous waste is emitted, and up to 98% of your oil is recovered!

Bulldozing the tank clean, utilizing manpower, loading and transporting waste materials, for many facilities, the conventional tank cleaning practice is expensive and risky. Choose our engineered approach, experienced personnel, and non-entry cleaning system.

Capabilities

No tank is too small or too large to be cleaned with our customized, engineered approach. With our expert knowledge in confined space cleaning and non-entry system, FourQuest Energy ensures your tanks are safely cleaned on time and on budget.

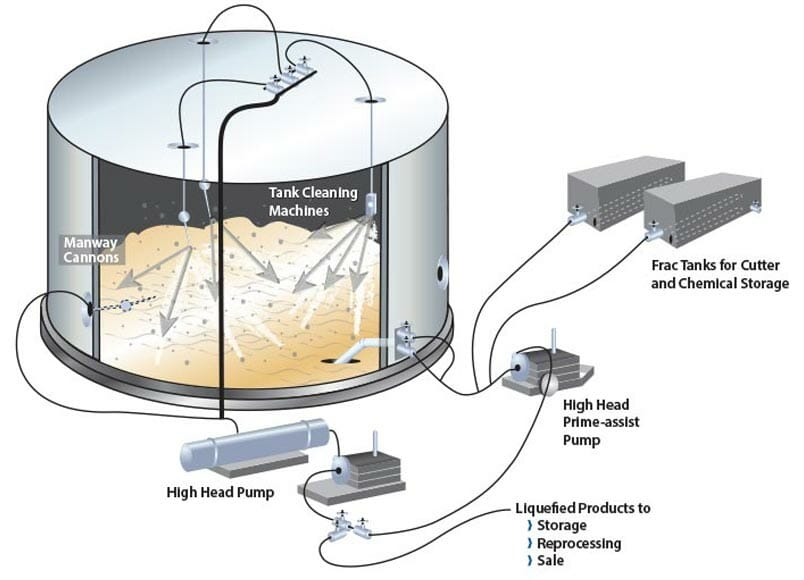

FourQuest Energy’s proprietary tank cleaning process enables you to clean your tanks chemically in a closed loop environment. First, we custom engineer a solution that liquefies the sludge deposits in your tank that would typically be removed mechanically. Then we blend the solution with a cutter stock and extract the content using standard circulation processes. Lastly, the tank is degassed and polished chemically, achieving a superior level of surface and air cleanliness. And it can all be done without the entry of people or the exit of contaminated waste.

The Results

- Less exposure to safety risk

- Lower project costs

- Recovered hydrocarbons

- Less environmental harm

Improve Performance

Financial Performance

This methodology can create millions of dollars’ worth of financial value plant wide. It’s a significant change in the way the world’s most efficient facilities will deal with tank management.

This financial performance is achieved in three ways:

Slashing Disposal Costs

The disposal of hazardous waste from your tank can cost between two and four times as much as the actual cleaning of it! Hazardous waste disposal is one of the industry’s most costly burdens, and the fees and potential fines grow increasingly more expensive. Packaging. Transportation. Storage. Then the disposal itself. It really adds up.

With our chemical tank cleaning process, organic solids are dissolved inside the tank, letting you avoid expensive hazardous waste disposal expenses. Only non-hazardous materials are left. And with those costs relatively attractive, you’ve just eliminated one of the largest financial tank cleaning burdens.

Expediting Execution

Faster scheduling means less down time so that your plant can get back to operational capacity.

Recovering Hydrocarbons

Rather than creating waste for disposal, recycle it using our solvent cutter. Take this opportunity to generate revenue rather than creating costs.

Environmental Performance

Our advanced chemical tank cleaning process also minimizes waste, leaving only insoluble, non-hazardous materials for disposal. No more reporting tank hazardous waste disposal to your environmental regulatory agency. No more digging up contaminated soil around the tank. Reduce your hazardous volume on a massive scale.

Want to protect your crew, save money, and improve your unit’s environmental performance? Contact us today to learn more about our chemical tank cleaning process.

Safety Performance

Our chemical tank cleaning methodology reduces or eliminates the requirement of personnel to enter the tank; work is performed in a closed loop system. Our chemicals are the all the work inside the tank and when finished all of the hazardous materials are flushed out of the tank all without people exposure!

System & Operations

Step 1: Recoverable Hydrocarbon Extraction

FourQuest personnel blend a hydrocarbon diluent (cutter stock) with the selected chemical additives (FQE® Solvent-H) and establish liquid circulation loops. Sludge deposits, which would otherwise remain as solids for disposal, are liquefied and can be pumped from the tank more efficiently for further processing. The liquid circulation loops are established using standard pumping equipment and through manway and roof-mounted cleaning nozzles that can be directed to any location within the tank.

Step 2: Tank Degassing and Polishing Cleaning

After the hydrocarbon extraction phase is complete, the tank is degassed and cleaned of any nominal hydrocarbons by use of state of the art degassing / decontamination chemistry. These products are non-hazardous water encapsulants which perform to scrub the tank air space of all hydrocarbon vapours and clean the tank interior surfaces of residual oil films.

Non-Entry High Pressure Cannon System

Equipment Specs

- 2 High Pressure Cannons (manway mounted)

- 45m3/hr Injection Rate @ 260 Psi (Max)

- 100% Explosion proof

- Remotely Operated via Control Room

- Mounted HD Camera

- Mounted Gas / Oxygen Detection Monitor

- Audio / Visual Alarm / Emergency Shutdown

- Cannon extension and rotation capability

- HMI Touch Screen / Real Time Visual Display

- DVD Recorder

- Heads Up Intrinsically Safe LED Lighting