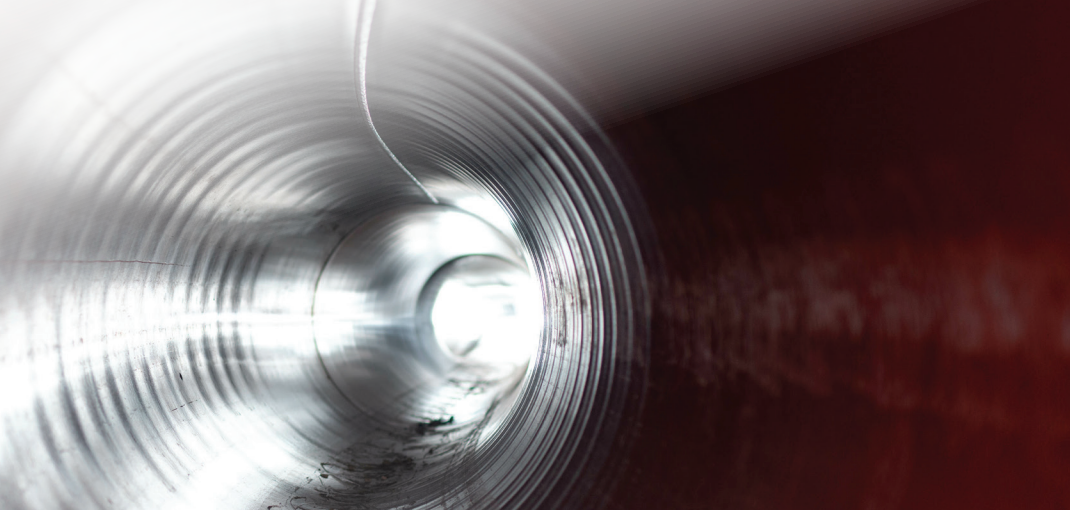

Pipelines require strict dew point control to ensure control of the corrosion environment on the pipe surface and product quality control.

Pipeline drying is a critical phase of pipeline commissioning in new construction and when the system has been opened to the atmosphere for maintenance. The integrity program of pipe assets also includes engineering control of the system’s environment before feed in.

FourQuest Energy, a global leader in technical services to pipelines works closely with operators to understand their pipeline specification requirements and engineer fit-for-purpose solutions for dew point control in all types of piping systems. Our extensive experience in oil and gas guides our solutions and execution plans so operators are assured of proven techniques and predictable outcomes.

FourQuest often factors nitrogen use to achieve dew point control in pipe systems. Nitrogen use results in an inert atmosphere in the pipe environment and being a very dry gas, achieves low dew points quickly and efficiently. Vaporizing liquid nitrogen to gaseous nitrogen results in an expansion factor of 694 times; this powerful characteristic allows for a very compact footprint of equipment along the pipe right-of-way yet delivers a large gas volume impact to drying any size or length of the pipe system.

Understanding and analyzing our client’s goals and restrictions is the starting point of all engineering. We

are curious by nature and ask a lot of questions so we can deliver, with assurance the results of the campaign safely and responsibly – we are a best practices company.

FourQuest is sensitive to costs and approaches the client’s needs with sound economic reason. Sometimes the use of nitrogen in purging may be cost-prohibitive. In such cases, FourQuest is often relied upon to design pipeline dew point by using dry compressed air with a technique that creates turbulence at the pipe wall resulting in rapid drying without the need for laborious pigging. We firmly believe that with the correct engineering controls, every job can be designed

and completed safely.

While FourQuest has the most advanced fleet of nitrogen and air compression equipment in North America, our most valuable asset is our people. We are well-trained, competent, honest, and hard-working people who make good decisions regarding safety, the environment, and the public.