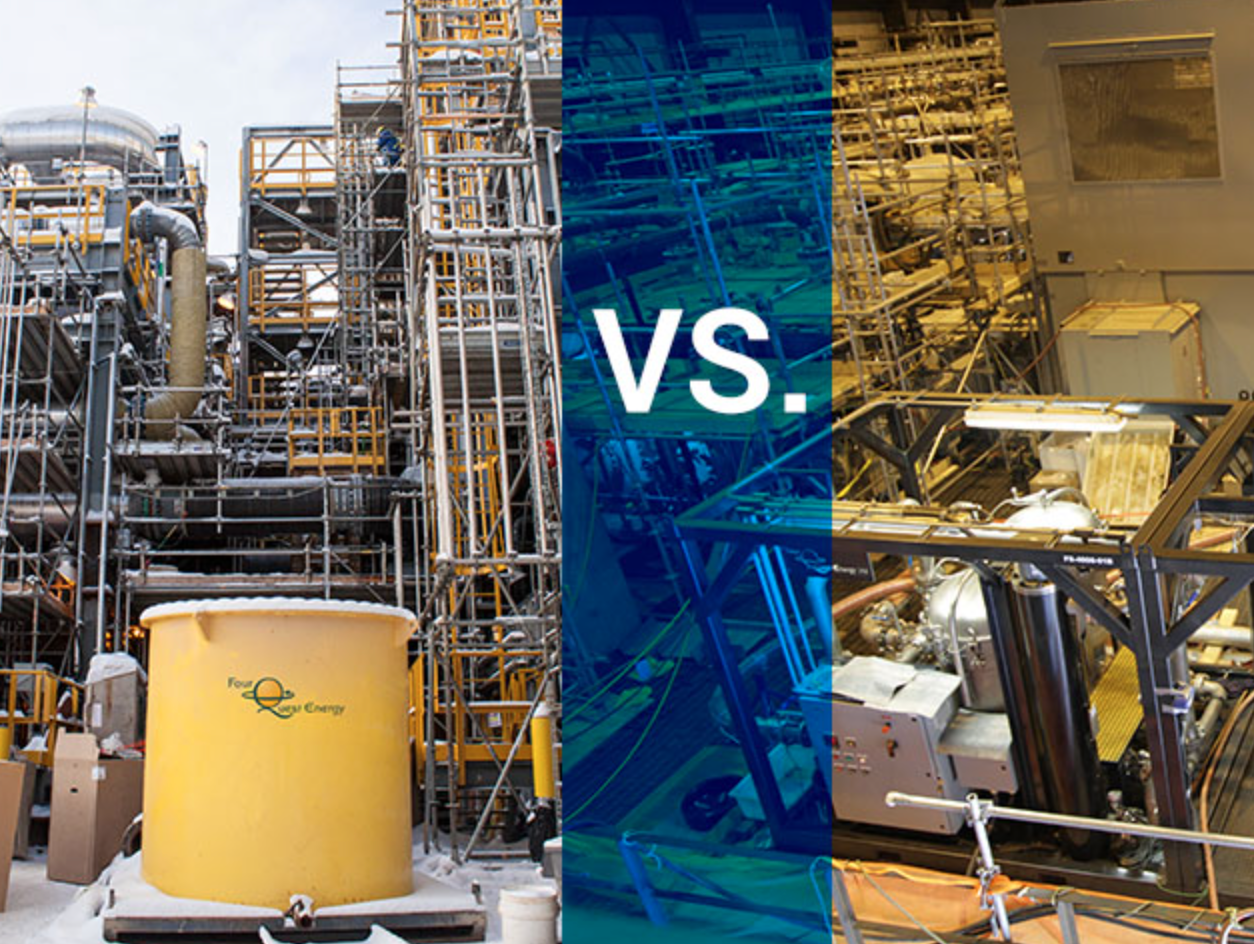

During the pre-commissioning process, systems must be rid of loose debris and hydro testing fluid prior to start up. The two most common methods for this type of system cleaning are air blowing and high velocity flushing.

Engineered Air Blowing

Engineered air blowing is an efficient way to remove construction debris, loose rust, liquids and other contaminants from process piping. Every air blow procedure is specifically engineered for the individual system being cleaned. This approach provides numerous benefits for our clients including; time effective execution by sequencing the blows in an efficient manner, thorough cleaning ensured through achieving a preferred cleaning force ratio of at least 1.5 (CFR > 1.5) and safe field execution by following the best industry practices. The Cleaning Force Ratio (CFR) is a measurement which compares the force generated within the piping during cleaning versus normal operation. The three most common and effective air blowing methods are:

- Decompression: In a standard decompression blow configuration the piping to be cleaned is pressurized with an air compressor and dryer to the required calculated pressure, then the air is quickly released from one end of the piping and the rapid depressurization of the piping blows any loose debris out of the pipe

- Pulse: When access to connect temporary equipment is restricted at the exit of the piping a vessel rupture blow can be performed. Air is compressed in the vessel and then rapidly released by the quick opening valve at the vessel propelling air through the system removing all loose debris.

- Continuous: To perform a continuous air blow, one or more air compressors, coupled with an air dryer, is connected to one end of the system. The output of the dryer is then slowly opened and the air velocity in the pipe is brought up to a maximum. This method is effective for cleaning small diameter lines. Our air compressors can produce 150 psi at up to 1600 scf/m. The compressor and dryer setup can produce air with a dew point down to -60˚C for efficient drying of systems. In addition, systems can also be checked for integrity by confirming the absence of leaks or passing valves during the pressurization.

Air blowing provides several unique advantages including a quicker rig in/out time, and reduced waste generation when compared to other pre-commissioning methods. Air blows can be conducted on almost any process system (ie. water, steam, chemical) which makes them ideal as a single equipment spread can clean an entire unit. Upon completion of air blows, the line is left clean and dry, which is preferred for long-term preservation methods, if required. Cleanliness can be measured using a variety of techniques from dewpoint to targets.

Disadvantages of Air Blowing

However, air blowing does have its disadvantages. It is not an efficient cleaning method when there is ice build up in the system. The air will not be sufficient to melt the ice, effectively removing it. If the system has been hydro tested with glycol, air blowing will not achieve dewpoint. Lastly, line size consistency is necessary. Too severe of line size reductions can reduce the efficiency of the air blows creating locations of trapped debris.

High Velocity Flushing

High velocity flushing provides an efficient method of removing debris from pipelines and newly constructed systems. By attaining the specifically engineered cleaning force ratio the circulating fluid is able to remove debris from the internal surfaces of pipe walls. The debris-laden fluid can then be filtered and re-injected to remove additional debris. Throughout the process, our personnel monitor the progression of the flush and conduct onsite particulate analysis to assess system cleanliness.

The advantages to this service include an easy to measure flow rate/velocity. This can be critical to ensuring the necessary CFR is being met to achieve cleanliness. Cleanliness is easily determined using visual inspection or filtration. High velocity flushing is ideal on water systems where neither draining nor drying are required.

Disadvantages of High Velocity Flushing

The biggest disadvantage to high velocity flushing is the complicated rig in/out. Often times significant amounts of piping, hoses, temporary pumps, and filters are required to perform a single flush. There is a substantial amount of waste generated if the system requires draining upon completion of the flush. Finally, water flushing needs to be conducted in warmer months, as the cold weather can create potential freezing issues in the flushing loops.

Each of these methods comes with advantages, disadvantages, and preferential applications. However, air blowing provides a more versatile, cost effective service option for the removal of loose debris and hydro testing fluid.