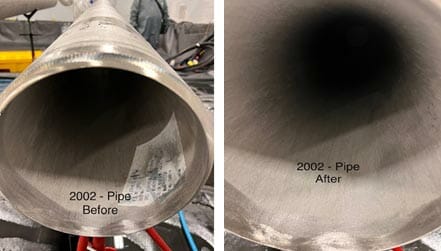

Prior to startup of equipment, it is necessary to ensure that residual hydrocarbon contamination, construction debris, and foreign objects are removed from the gaseous Oxygen pipe with no impact to personnel, equipment, or the environment. Due to the requirements of the Oxygen system, there cannot be any particulate or discoloration and since a higher level of cleanliness is required.

Safety Concern of Gaseous Oxygen Piping

An oxygen system is inherently dangerous because of the contaminates or foreign object debris that can ignite and support sustained combustion. All piping systems have ignition mechanisms. A safe oxygen piping system is one where all ignition mechanisms are inactive. Metallic piping fire events most frequently occur when one or multiple ignition mechanisms are present and active.

In an oxygen-enriched atmosphere, materials have a lower autoignition temperature. When metal filings burn, the temperature can exceed 2700°C, which is twice the melting temperature of the pipe material. Any residual contamination has the potential to become an ignition mechanism that could initiate an oxygen fire.

Oxygen Cleaning Techniques

Hand Cleaning

Cleaning method using hand tools such as wire brushes, scrapers, or other hand impact tools or combination of these methods to remove loose rust, loose welding slag and spatter, or loose mill scale.

Hand Wiping

A mechanical cleaning method using a clean, lint free cloth moistened with a cleaning solution or solvent to wipe small select areas only on components or systems. This procedure is preferred for smooth stainless steel surfaces rather than rough carbon steel surfaces.

Power Tool Cleaning

A preliminary cleaning method using power tools such as grinders, powered wire brushes and power impact tools can be used to remove loose mill scale, loose rust and loose paint.

High-Pressure Cleaning with Aqueous Cleaner

A mechanical process of applying an aqueous cleaning solution under pressure to a component or system. This will lift the contamination from the surface and facilitate the removal of contaminants while conserving more expensive solvents. This procedure is very suitable for pre-cleaning bolting and cleaning bulk piping materials. Pressurized spray washing with an aqueous cleaner must always be followed up.

High-Velocity Flush

The high velocity aqueous flush will ensure no harmful particles remain in the oxygen line piping. Flow rates have been designed for achieving a minimum fluid velocity of 3 m/s with a Reynolds number greater than 4000 to ensure a turbulent flow regime exists for the proper removal of particles. In addition, the flushing fluid will be heated to 60°C to improve the degreasing effectiveness of the industrial Cleaner. The increase in temperature will also reduce the water’s viscosity, which reduces the boundary layer thickness against the pipe wall and helps to increase turbulence.

Our industrial cleaner is non-corrosive, flammable, or toxic (either through vapor inhalation, skin contact, or ingestion). This cleaner helps to keep the equipment clean and corrosion-free.

Air/Nitrogen Blows

A cleaning process where a closed piping system is compressed with hydrocarbon-free air or nitrogen, and this gas is then quickly discharged to the atmosphere. The objective is that particulate debris is discharged from the piping system during this process. Therefore, repeated blows are typically required.

Inspection Techniques

Prior to installation, all equipment “Cleaned for Oxygen Service” must be inspected, as a minimum, by direct visual inspection, using both bright white light and ultraviolet light for contamination.

White Light Inspection

Metallic and non-metallic surfaces shall be inspected with a bright white light.

Ultraviolet (UV) Inspection

Any surface or area of a part that glows or fluoresces indicates possible contamination. Therefore, UV inspection is performed in a dark environment.