Effective in the removal of construction debris, weld slag, sand, oil, dust, rust and mill scale from critical systems prior to plant start-up.

We optimize our steam blows with quality engineering, and by utilizing the best equipment. Determining pipe sizing and design, pipe routing, steam conditions, noise level, thermal cycling, water quenching, and condensate generation are all factors that—with our proper planning—will ensure a successful steam blow operation.

Why Perform Steam Blowing

When pipe is fabricated during hot working, a heavy oxide layer forms. This layer is known as mill scale and must be removed from critical systems before putting them into service.

Over time, enhancements have been made in plant start-up techniques to perform engineered steam blows that remove mill scale. During a steam blow, the piping is blown with sufficient boiler pressure to ensure that enough dynamic pressure will be experienced in the pipe to provide adequate cleaning.

During any plant start up, there’s a possibility that particles left in the pipe from the construction phase could break loose and travel downstream. These particles can damage instrumentation and impede other plant operations. Typically, boiler pressures used in steam blowing provide a dynamic pressure throughout the piping that is at least 20% higher than would be experienced in normal operating conditions (CFR ≥ 1.2). Any potentially damaging particles will be blown out of the piping prior to plant operation.

The time taken for an object to travel through the system and be ejected cannot be calculated. Instead, a technique of detecting particles in the emerging steam blow is used. This technique checks the emerging steam for particles impacting on a polished metal plate (commonly known as a target).

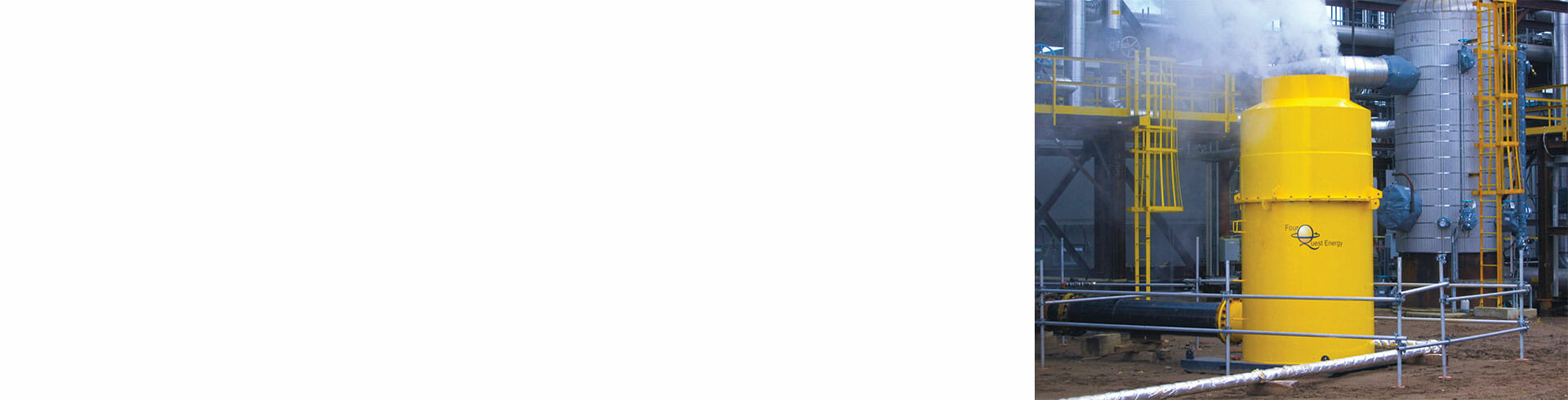

The steam blow method is similar to the exhaustive air blow technique, but the boiler is fired to generate the pressurized steam used to clean the steam path. Specialized quick opening valves and a detailed procedure, along with the design of temporary spools, steam quenching devices, silencers, and debris containing equipment are required to perform this service.

Related Case Studies and Industry Insights

Application

- Removal of residual post-construction debris

- Unseating mill-scale magnetite layer deposits and welding slag through thermal pipe shocking

- Purging high, medium, and low pressure steam lines leading to end users, such as well pad injection points, steam traps, etc

- Commissioning of steam supply and distribution piping, including lines originating from traditional boiler and OTSG systems

- Cleaning of critical system piping leading to crucial components, such as steam turbine generators on cogeneration units

- Precautionary maintenance on older steam systems where contamination is suspected for major critical repairs have been conducted

Steam Blowing Methods

High pressure cyclic blow method

In the cyclic blow method, the boiler is fired to gradually pressurize the system until a predetermined pressure is reached. Once achieved, a quick-opening valve is opened and the contained steam is released directly into atmosphere through the temporary piping and silencer; a transonic velocity is applied with a high mass flow rate. In order to employ the cyclic blow method, temporary piping has to be properly engineered, including stress analysis calculations.

Low pressure (continuous) blow method

For pre-commissioning, a continuous low-pressure steam blow technique has become standard practice for cleaning most steam system circuits. This method requires the steam generators to be continuously fired to generate steam velocities exceeding the velocities generated during normal plant operations. To control pre-determined steam conditions at the piping inlet, an orifice plate or sacrificial valve is used. The low pressure continuous blow method is used for both targeted and service steam blows.

Determining the Cleanliness of the Steam Blow

In order to provide a quantitative measure of system cleanliness, a technique of detecting particles in the steam exiting the blow is used. The emerging steam is monitored for particles by quantifying impacts on a polished metal plate commonly known as a target. Guidelines state the allowable quantity and size of particle impacts on the target.