https://www.fourquest.com/wp-content/uploads/2023/10/oxygen-line-cleaning.jpg

Oxygen Line Cleaning

Resources 1

https://www.fourquest.com/case-study/pre-commissioning-pneumatic-testing-of-oxygen-service-piping/

Pre-Commissioning & Pneumatic Testing of Oxygen Service Piping

Latest Case Study

https://www.fourquest.com/wp-content/uploads/2024/03/industry-insight-menu.jpg

Resources 2

https://www.fourquest.com/embracing-the-workforce-evolution-in-industrial-services/

Embracing the Workforce Evolution in Industrial Services

Latest Industry Insight

https://www.fourquest.com/wp-content/uploads/2024/03/resouces-menu.jpg

Resources 3

https://www.fourquest.com/resources/library/

Download all our marketing material in PDF format

Latest Case Studies and Data Sheets

https://www.fourquest.com/wp-content/uploads/2024/03/nitrogen-services-menu.jpg

Services 3

https://www.fourquest.com/services/nitrogen-services/

We have the largest fleet of nitrogen equipment in Canada

Your First Call Nitrogen Provider

https://www.fourquest.com/wp-content/uploads/2024/03/quest-for-zero-menu.jpg

Company enticer

https://www.fourquest.com/company/qhse/

Safety is our number 1 priority

Quest for Zero

https://www.fourquest.com/wp-content/uploads/2024/03/canadas-best-managed-logo.jpg

Third on the company menu

https://www.fourquest.com/news/fourquest-named-one-of-canadas-best-managed-companies/

FourQuest Energy is a 2024 winner of the Canada's Best Managed Companies Program

Latest News

https://www.fourquest.com/wp-content/uploads/2024/03/career-opps-menu.jpg

Careers

https://www.fourquest.com/careers/

Our possibilities are endless, discover yours

Worldwide Opportunities

https://www.fourquest.com/wp-content/uploads/2024/03/engineering-menu.jpg

Services 1

https://www.fourquest.com/services/pre-commissioning/engineering/

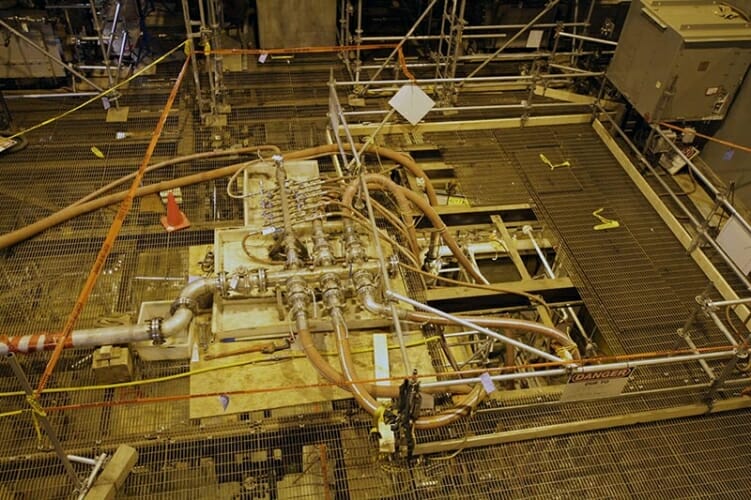

Everything we do in the field, we engineer first

World Class Engineering

https://www.fourquest.com/wp-content/uploads/2024/03/sponsorships-menu.jpg

Second post in company

https://www.fourquest.com/company/sponsorships/

FourQuest Energy is proud to sponsor the Wild Pony racing teams

Proud Sponsor

https://www.fourquest.com/wp-content/uploads/2024/03/oxygen-line-cleaning-menu.jpg

Services 2

https://www.fourquest.com/services/pre-commissioning/oxygen-line-cleaning/

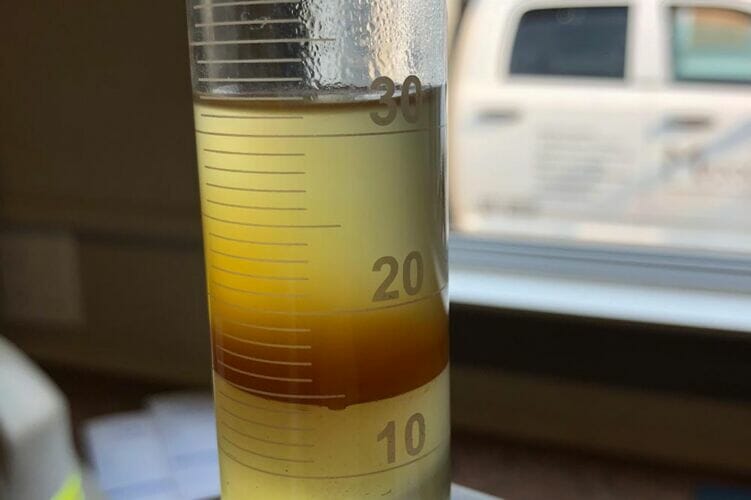

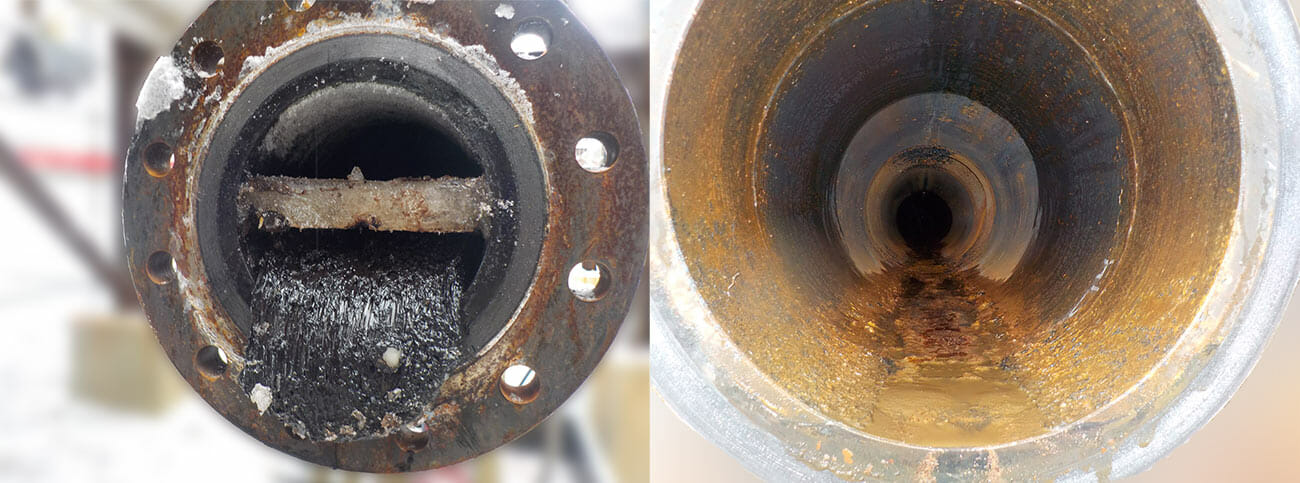

Ensure that residual hydrocarbon contamination, construction debris, and foreign objects are removed from the gaseous oxygen pipe.

Oxygen Line Cleaning